Distributed Inventory Tracking. Made Easy.

Track inventory across multiple sites, field teams, and customer locations—with no manual scans, no added infrastructure, and no blind spots

Inventory in Motion. Visibility Required.

Inventory is no longer stored solely in owned warehouses. From field reps and third-party logistics (3PL) facilities, to customer locations and vehicles in transit, goods are constantly in motion. Traditional tracking systems weren’t built for this level of mobility or distribution, leaving businesses without clear visibility into what they have or where it is.

Without real-time tracking, distributed inventory blind spots can lead to:

Stockouts and missed fulfillment

Items aren’t where they’re needed, when they’re needed—causing delays and strained relationships

Wasted time and excess ordering

Teams lose hours tracking inventory, or duplicate orders for items sitting unseen at another location

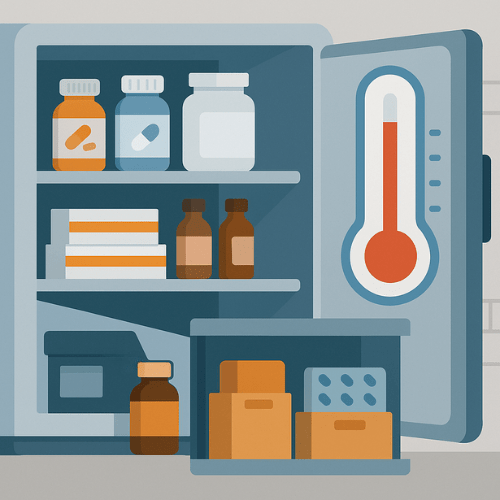

Quality and compliance risks

Perishables and sensitive goods can degrade unnoticed—causing safety issues and spoilage

Lost accountability

Field reps are always moving, and partners have other priorities—making manual tracking inconsistent and records unreliable

Disputes and write-offs

Without digital proof of location, usage, or chain of custody, businesses face financial risk

Lack of auditability and system trust

Without automated tracking, teams lose trust in reported inventory levels—leading to workarounds and disconnected workflows

Who Needs Distributed Inventory Tracking?

Healthcare & Life Sciences

Suppliers managing consigned surgical implants and temperature-sensitive goods across hospitals and surgical centers

Energy & Utilities

Operations teams maintaining visibility of critical spare parts across substations and remote field sites

Consumer Goods & Distribution

Distributors and brands tracking high-value or regulated inventory consigned to retail locations

Field Services

Service organizations and technicians managing diagnostic tools, equipment, and supplies on the move

Use Case Spotlight: Medical Devices & Transplants

For medical device manufacturers and organ transport coordinators, every second and every item matters. Lives depend on ensuring that necessary supplies, such as implants, organs and the associated surgical tools are available, viable, and at the right locations at the right time.

Why Traditional Tracking Methods Fall Short

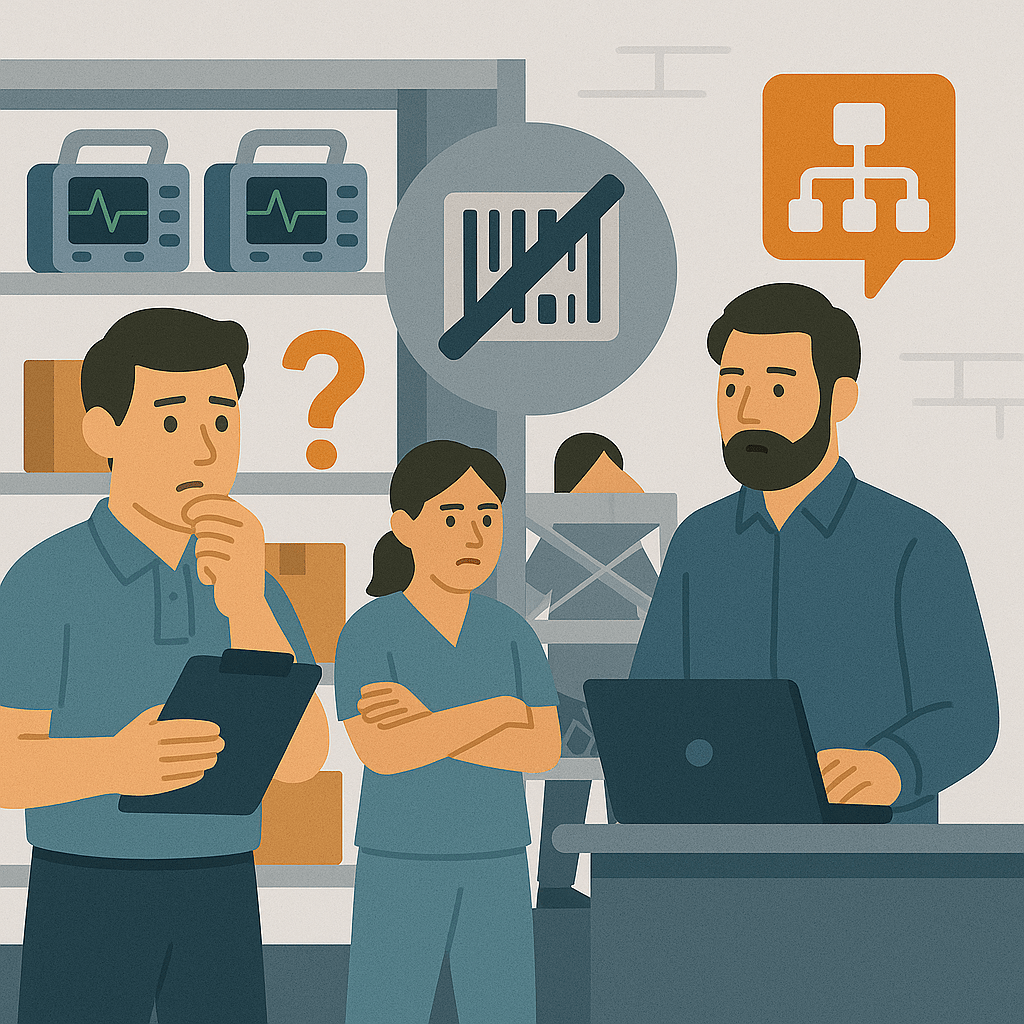

Millions of items, thousands of locations

Managing large inventories spread out between carriers, reps, and hospitals requires tracking at scale

Manual scanning falls short

It’s time-consuming, disrupts workflows, and often gets skipped—leading to errors, delays, and lost inventory

Infrastructure headaches

Equipping reps with readers is costly, and installing fixed RFID at hospitals is often impractical or restricted

Everyone needs visibility

Medical device makers, their reps, and hospitals ALL require visibility

The Luna Solution

Luna is a Bluetooth-powered tracking solution built for complex, distributed inventory networks—delivering real-time visibility without requiring manual input or new infrastructure

Automated visibility

Inventory updates in real time—no scanning required

No new infrastructure

Use existing tablets, scanners, or mobile devices as trackers

Fast, intuitive tracking

Quickly pinpoint items with radar view, on-map displays, and proximity alerts

Complete coverage

Can track inventory across hospitals, customer locations, and the field with minimal workflow disruption

Affordable and long lasting

Luna tags can be attached at tote–or item–level, cost a small fraction of traditional tracking solutions, and last up to five years on a charge.

Audit-ready records

Maintain a full digital history of each item’s location, temperature, and usage—ensuring safety, quality, and compliance

Deploy Luna in days, scale across hundreds of locations, and integrate with your ERP or inventory management system via API

Fast to Deploy, Easy to Scale

Track inventory wherever it’s stored or used—without complex infrastructure or IT delays

How it Works

Choose the best suited Luna tag for your use case (location only, location + temperature, autoclavable). Attach tags to inventory

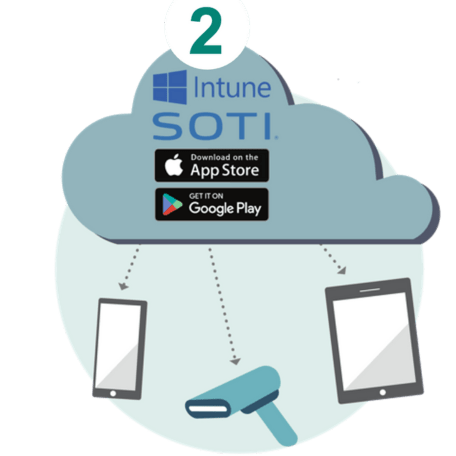

Activate Luna Locate on mobile devices via MDM or app store download. No manual pairing with tags required

Inventory data syncs automatically with your ERP or inventory management system, plus Luna desktop and mobile apps