Manufacturing Asset Tracking. Made Easy.

Real-time tracking for parts, tools, and work-in-progress items across large facilities and storage yards—no manual scans, no costly infrastructure

Asset Tracking in Non-Linear Manufacturing

Whether it’s building tractors, buses, or heavy equipment, manufacturing often involves a complex, non-linear flow of components and subassemblies. Work-in-progress (WIP) units are sent off the production floor to outdoor yards, supplier parts and tools are stored in staging areas.

Without real-time asset tracking, manufacturers face:

Production delays

Misplaced items stall assembly and lead to missed delivery windows

Inefficient replenishment of parts

Inaccurate inventory counts lead to over-ordering, idle stock, or costly last-minute resupply

Lost or under-utilized assets

Tools and parts go missing or sit unused due to poor tracking

Quality risks and rework

Parts may degrade without condition monitoring or storage duration tracking

No trusted system of record

Without real-time updates, ERP or MES platforms lack reliable location data

Missed SLAs and lost customer trust

Delays erode trust and jeopardize repeat business

Who Needs Non-Linear Manufacturing Asset Tracking?

Heavy Equipment Manufacturers

Tractor, bus, forestry equipment, dump truck, or trailer OEMS

Internal Production & Operations Teams

Manufacturing staff managing and tracking WIP units

Procurement & Inventory Management

Teams ensuring supplier parts are stored properly and ready when needed

Use Case Spotlight: Tractor Assembly

A leading tractor OEM moves partially assembled products to indoor staging areas or an outdoor holding yards while awaiting components for final assembly. Without real-time visibility into where specific WIP units, tools, and parts are located, delays and disruptions are common. Partially built tractors tie up working capital, and staff waste time locating them, components, and tools, and supply teams often overstock parts “just in case,” only to misplace them or leave them unused until they’re obsolete.

Why Traditional Tracking Methods Fall Short

Manual scanning breaks down

With high volumes of moving parts and pressure on staff, scans can easily get skipped

RFID needs fixed infrastructure

Chokepoints for fixed readers aren’t always available in outdoor yards or dynamic production areas

GPS fails indoors

GPS fails indoors and around metal—making it unreliable on the production floor or in storage areas

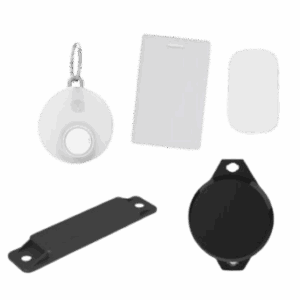

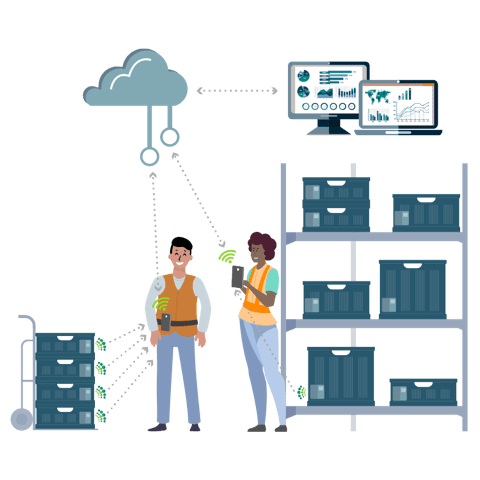

The Luna Solution

Luna is a Bluetooth-based tracking platform that brings real-time visibility to non-linear manufacturing environments. It requires no chokepoints, no staff retraining, and no costly infrastructure. It runs on devices you already have—automatically capturing real-time location data across production floors and holding yards, both on and off-site.

Low-cost, high-impact

Bluetooth now rivals passive RFID in cost—without the need for fixed readers or complex setup

Uses what you have

Existing tablets, scanners, and mobile devices become tracking gateways–no new hardware needed

Automated & real-time

Know where your inventory is with no manual scans, and minimal change to staff workflows

Find parts fast

Radar views and proximity alerts guide teams to missing components quickly

Full traceability

Get a complete digital audit trail for every tagged part—supporting compliance, replenishment, and quality control

Condition-aware

Track temperature and humidity to protect sensitive components in storage, in transit, or off-site

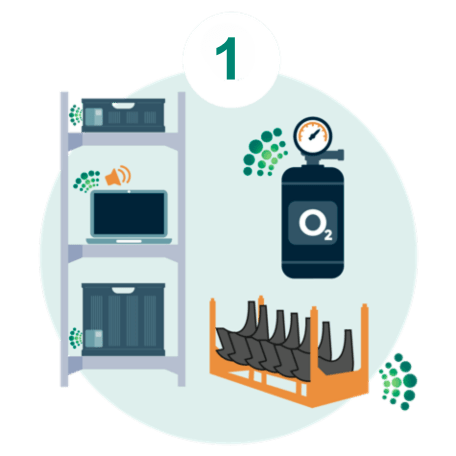

Fast to Deploy, Easy to Scale

How it Works

Attach Luna-enabled Bluetooth tags to inventory and assets

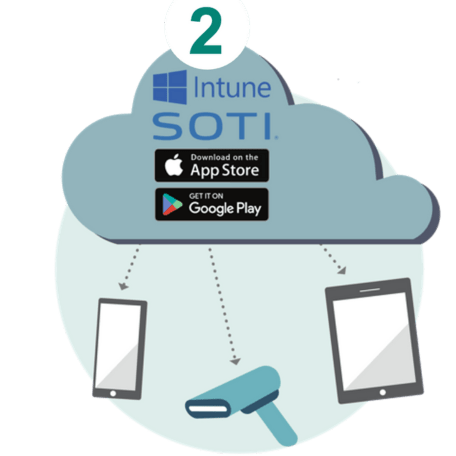

Activate Luna Locate on mobile devices through MDM or app store download. Add fixed gateways or WiFi access points for greater detail

Real-time location and condition data syncs automatically to Luna apps, and/or your existing ERP, MES, or asset management systems