Returnable Container Tracking.

Made Easy.

Track containers across your own facilities, partner facilities, and in transit—no manual scanning, logging, or new infrastructure required

Why Returnable Container Tracking Matters

Returnable containers are essential across industries—from IBCs used in food and chemical manufacturing, to automotive racks, pallets, and totes. But with containers moving between suppliers, 3PLs, retailers, and through inspection and sanitizing facilities–tracking can be complex.

Without real-time visibility, operators face:

Fulfillment disruption

Missing containers delay orders and force costly last-minute workarounds like re-picking, re-palletizing, or rerouting shipments

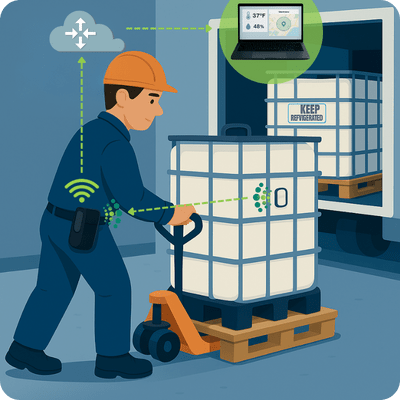

Spoilage

Without accurate temperature monitoring, perishables and sensitive items can be unknowingly compromised

Expedited freight costs

When containers aren’t available, companies pay to rush replacements in–or pay for faster final product shipping to meet delivery schedules

Product damage and expendable container costs

Expendable containers add extra costs and often provide less protection than purpose-built ones

Stalled production

Without containers, there may be nowhere to safely store finished product–forcing line shutdowns, machine downtime, lost output, and costly overtime to recover

High replacement costs

Replacing purpose-built returnable containers can range from hundreds to tens of thousands of dollars

Use Case Spotlight: Tracking IBCs Across Partner Sites

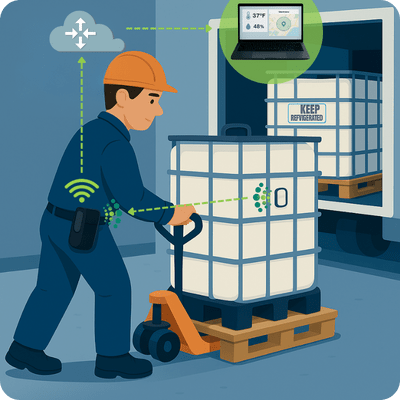

An industrial food processor uses intermediate bulk containers (IBCs) to move ingredients between plants, co-manufacturers, and storage facilities. Some are temperature-sensitive. Others carry allergen risk. None can be replaced quickly or cheaply.

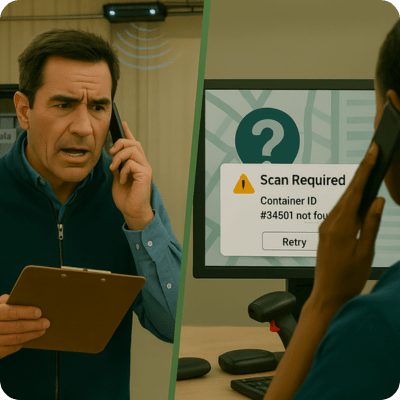

Without automated tracking, staff rely on manual check-ins or phone calls to figure out where containers are. Visibility gaps lead to costly delays, spoilage, or non-compliance with food safety protocols.

How Traditional Tracking Methods Fall Short

Limited cross-party visibility

Most tracking systems rely on RFID infrastructure at chokepoints or manual scanning. Partners are often neither equipped, nor have time, for either

GPS with cellular too costly to scale

Traditional GPS with cellular trackers are too expensive. To be viable at scale, per-trip tracking costs must stay below $0.10

No shared system of record

When containers change hands, data is often lost. Suppliers, shippers, and customers all need visibility, but rarely share a platform

The Luna Returnable Container Tracking Solution

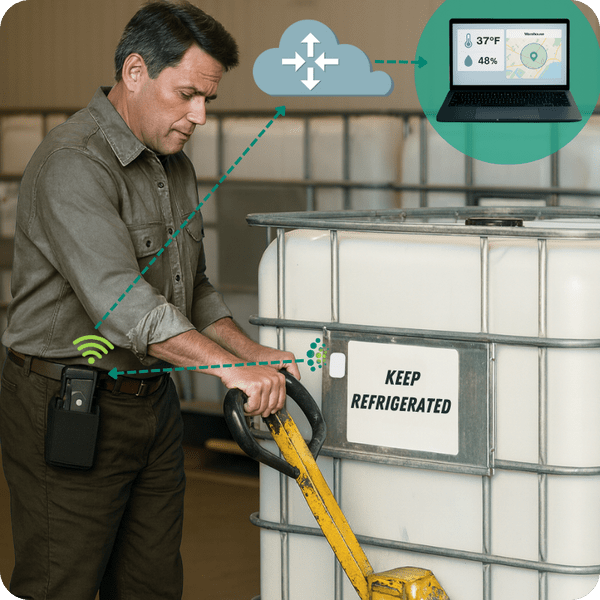

Luna is a Bluetooth-based tracking platform that makes container visibility automatic, affordable, and scalable. It works with the devices you and your partners already use—no manual scanning, no new infrastructure to install, and minimal disruption to operations.

Automated tracking

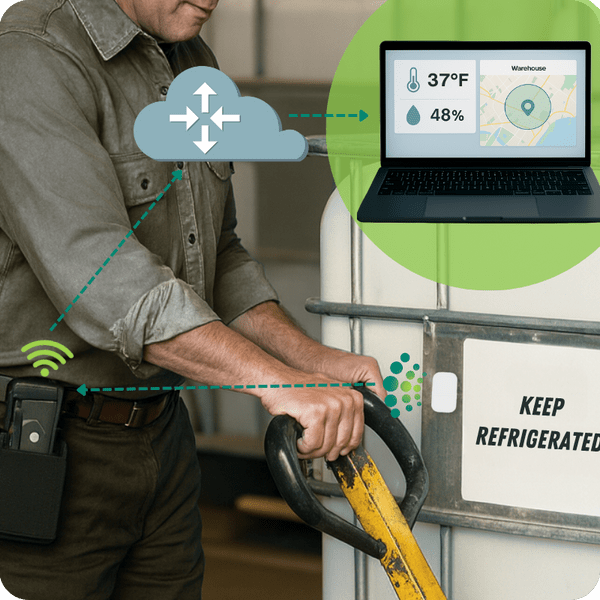

Luna tags report real-time location and condition data automatically—no manual scans, check-ins, or input required

Low cost, high impact

Use existing tablets, scanners, and mobile devices as trackers–no new infrastructure, no complex setup, no manual pairing. Deploys in days, not months

Tag flexibility

Select tags based on size, price, lifetime, sensor and even GPS capabilities

Condition monitoring

Monitor temperature and humidity to prevent spoilage, support compliance, and protect product integrity

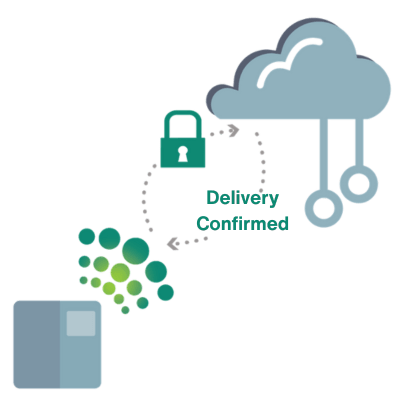

Secure and reliable

End-to-end, bi-directional encryption ensures data reaches its destination and stays protected

Built for Container Tracking

Track containers at your facilities, in transit, or at partner locations—without complex infrastructure or IT set-up

Simple Set Up for Returnable Container Tracking

Attach Luna tags to IBCs, racks, totes, or other returnable containers

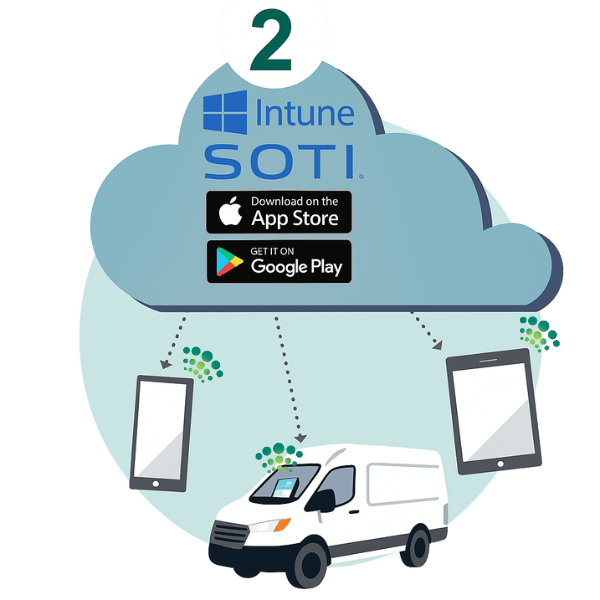

Activate Luna Locate on tracking devices via MDM or app store download

Container data syncs automatically with Luna apps or your existing ERP/WMS platforms