Reusable container tracking doesn’t have to be a chore

…and neither does tracking your shipments and contents

Reusable containers are great. Convenient, durable, easy to stack and ship.

And easy to lose track of.

Now, what if you could not only keep track of your containers–so you can ensure you always have the right numbers in the right places–but also know if perishable, dangerous, or valuable shipments are being handled properly? And what if all you needed for that level of reusable container tracking was an inexpensive tracker about the size of your thumb?

Oh and it’s dead simple to set up, use, and maintain.

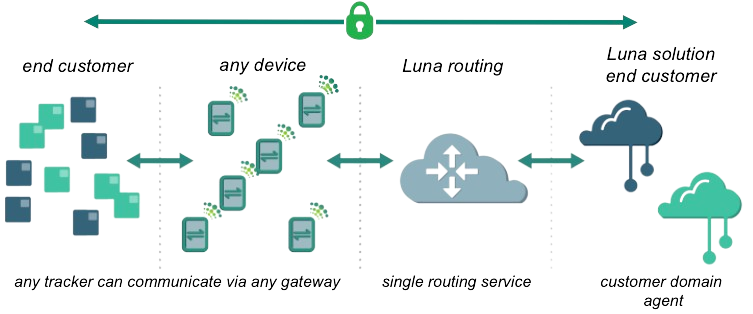

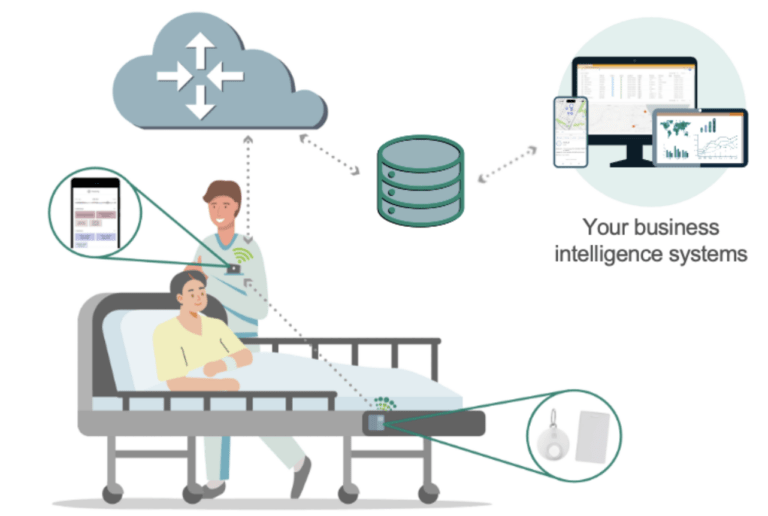

A new generation of Bluetooth Low Energy (BLE) sensors and trackers enabled with the Luna communication protocol can provide location and environmental data in small form factors that can be easily attached to containers of all types. More advanced trackers can include optional LTE connections for always-on connectivity when other networks aren’t available.

These Luna-enabled sensors and trackers can be deployed in bulk and don’t need additional expensive hardware or infrastructure. They connect to your existing network using devices such as handheld barcode scanners, work phones, tablets, computers, and Wi-Fi routers. These advanced trackers and sensors are designed to solve today’s logistics and tracking issues so you can focus on what matters–building your business.

Manage the entire life cycle of your containers

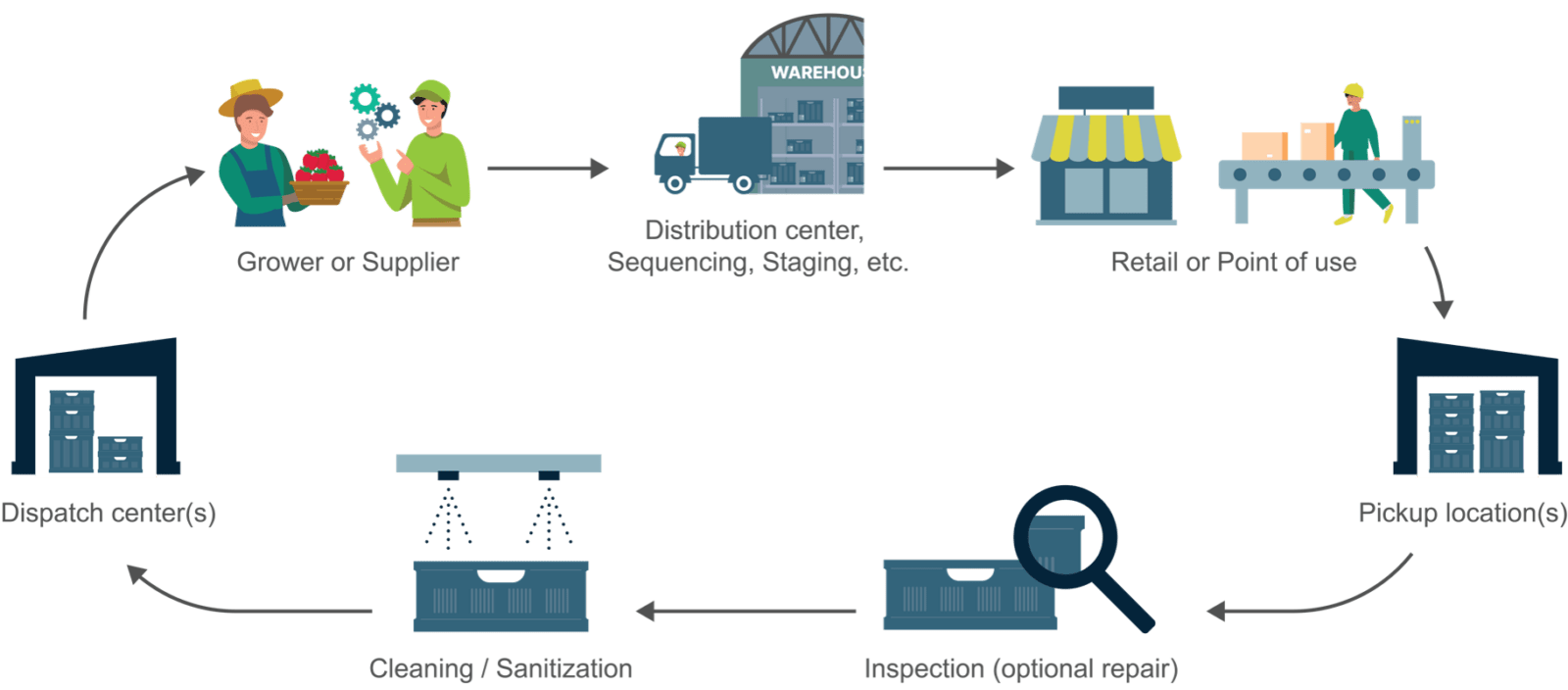

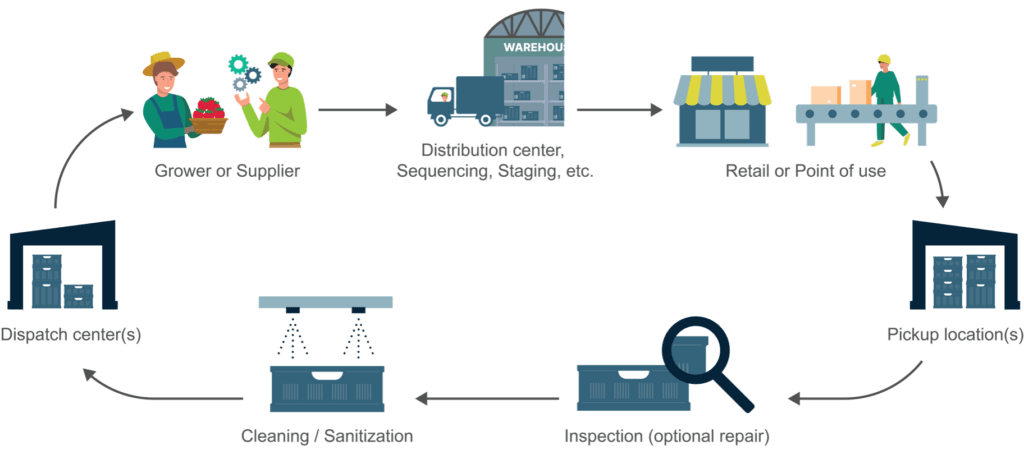

For most suppliers, their container journey looks something like this:

At every point in the chain you need to know not only where the container is, but its status and the status of the goods inside. Unfortunately, this is what the lifecycle of your containers really looks like:

Without effective reusable container tracking, once containers leave your facility, you don’t have any idea what’s going on with them. At least until you get a call like:

- “This is your supplier. We’ve run out of approved returnable containers. Can we switch to the backup expendable packaging? It’s more expensive, but without it, we’ll miss the shipment.”

- “This is your distributor, your pallets are piling up. Could someone come get them or we’re going have to throw them out?”

- “This is Grocery Brothers. About half of your blueberries are unsellable; they must have gotten too warm in transit and are growing mold.”

… which sends people scrambling to get containers from the wrong place to the right ones and figure out why a shipment arrived at the store a disgusting (and expensive) mess. What you need–and what has been missing in the market until now–is an inexpensive solution to give you real-time information on where all your containers are and the environmental conditions around them.

Old problem, new solutions

Losing containers, having too many in one place and not enough in others, and limited data on shipping conditions or locations are issues that have been around since people started moving goods from one place to another. In the past, solving this problem required manual scanning or significant investments in expensive technologies and infrastructure.

Many producers and carriers can’t afford to deploy RFID reading infrastructure in their facilities, and equip all their drivers with yet another device for scanning containers (let alone assume that they will always do so) for reusable container tracking. And these solutions would likely only provide data at endpoints in the chain. You could scan leaving your facility and when the shipment arrived at the warehouse, but between those points–nothing. You would have no idea where your shipment was, if it was getting too hot, too cold, or jostled en route–until it was too late.

New BLE trackers and sensors connected by the innovative Luna communications protocol, leverage something around us all the time: Bluetooth-enabled devices. These trackers and sensors connect through an app on existing company devices (e.g. barcode scanners, workphones, tablets, etc.) to relay the data from the sensor to the cloud where it’s securely transmitted to your systems in real-time. You’ll know exactly where all your containers are at all times–even en route by using a driver’s device to transmit the data. You can be alerted if shipments are too hot or cold. You’ll have a live inventory of where all your containers are so you can keep your supply chain moving.

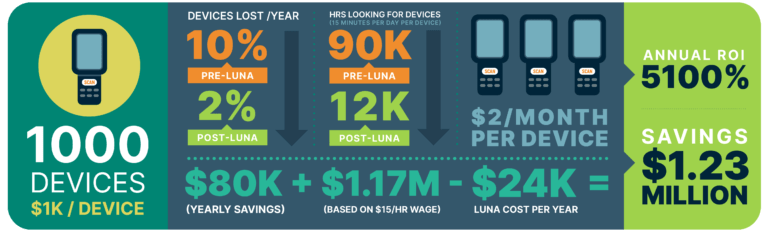

The revolutionary Luna XIO system combines inexpensive trackers with the infrastructure you already have to give you something you haven’t had before–peace of mind. And this peace of mind doesn’t break the bank either. You can have reusable container location tracking, and environmental data, at prices an order of magnitude less than RFID-based solutions or traditional data loggers.

Once you have your Luna-enhanced shipping process set up, you’ll know where all your containers and shipments are, and their condition. You can make sure your whole supply chain is moving efficiently and you can save money on lost shipments, unnecessary trips to move empty containers, and ensure your products arrive on time, intact, and ready for market.

Now it’s your turn

See how Luna XIO’s groundbreaking Bluetooth-to-cloud system can solve challenges in reusable container tracking, environmental monitoring, loss prevention, and inventory management.

Leveraging your existing infrastructure, Luna XIO can be set up in about a week utilizing mass-deployed BLE tags and an MDM-deployed app to company barcode scanners, mobile computers, and smartphones. You’ll be able to receive crucial telemetry data like location, temperature, and sudden shocks right in your existing ERP systems.

Start saving money on lost containers, spoilage, theft, and production delays with BLE sensors and Luna XIO. Industry insights show how reusable container solutions contribute to both operational efficiency and environmental responsibility, as highlighted in these perspectives on the operational and environmental impacts and innovative packaging solutions.

To learn more or book a demo, visit lunaxio.com/consult.