Roses Are Red, Violets Are Blue, We Make Cold Chain Monitoring Easier for You

A lot goes into making sure Valentine’s flowers are fresh for that special day

Americans spent over $21B on Valentine’s presents in 2023 and over $2B on flowers alone. Millions and millions of flowers are shipped around this time of year to meet the demand for this one day. And since it’s winter in the Northern Hemisphere, most of these flowers have been making their way to flower depots for weeks now.

So, how do you make sure those roses will rise to the occasion when they were picked a month ago? You keep them cold. Then the question is, how do you know they’re kept cold? Cold chain monitoring. Then the question is, well what’s the problem? If it’s monitored it’s all good, right?

Not always.

For much of the industry, cold chain monitoring means the temperature and humidity are logged by trackers that aren’t checked until the shipment reaches its destination. If there is a problem with cold storage, and no one notices, those flowers could be worthless when they arrive. The only way to make sure all those millions of flowers arrive fresh as a daisy is to have real-time, actionable data in the hands of people who can do something about it.

Until recently, getting that data hasn’t been cost-effective. GPS-based tracking is expensive and requires sophisticated hardware to install, configure, and maintain. Making do with what everyone except the biggest carriers was doing would have to do.

Not anymore.

Luna XIO’s award-winning Bluetooth-to-cloud solution uses Bluetooth Low Energy (BLE) devices connected to your existing network and hardware to securely collect, encrypt, transmit, and distribute data in real time wherever devices can reach the internet. With Luna you can reliably track your shipment and take action before it’s too late and a shipment is ruined. And for a lot less than any other solution available. Luna focuses on making sure you not only get your data, but that the data can be integrated into existing systems for actionable dashboards and alerts. Imagine knowing as soon as a shipment was getting too warm, so you can have a driver pull over and check, versus finding out when it’s already too late.

What’s so special about tracking flowers?

Cold chain monitoring isn’t just about flowers, though that’s big business this time of year. Our global food supply system relies on shipping food long distances at constant temperatures. Regardless if it’s by truck, train, or ship, perishables need to be kept cold. As we covered in our Thanksgiving post about turkeys, often sensors are only checked at delivery and sometimes they don’t accurately record what’s going on inside a truck. It might not be a health crisis to have a container of roses arrive not so rosy, but for the industry as a whole, knowing how cold shipments are in real time can make the difference between roses are red and roses are rotten. And when you expand that to the entire food transportation network, reducing food waste saves billions of dollars and gets food to the people who need it.

Cold chain monitoring is crucial to supply chains today. With applications from flowers to food to healthcare, Luna XIO is poised to make it possible to know the state of anything you’re shipping from the moment it’s packed to the moment it’s delivered–even if it’s being delivered to a person’s home.

The thorny issues with existing cold chain monitoring solutions

Traditional or legacy solutions suffer from four big problems:

- Lack of (cost-effective) real time monitoring

- Systems that don’t connect and integrate with other parts of your organization

- High cost for hardware, installation, integration, and training

- Relying on manual scanning introduces human error into what should be an automated process

The problem with legacy systems is the hardware they use, like data loggers and passive RFID, can’t reliably transmit data in real time. Most of the time data is gathered in transit and then checked on delivery. So you only know if there were issues with the shipment when it’s too late. And even then, many legacy systems don’t have the granularity for gathering data throughout a trailer or to the individual pallet level. Part of a trailer’s temperature could be fine, but the rest isn’t, and if you want to salvage a shipment, that means someone has to check the entire shipment. We all know, most of the time it’s easier to just toss the entire thing than waste time checking.

Wouldn’t it be better to have sensors that can seamlessly connect to existing infrastructure like a driver’s mobile phone and securely transmit data as it’s gathered?

Most legacy systems use proprietary hardware and software. Not only do you have the problem of vendor lock-in, but these systems are difficult to connect to enterprise systems. When you have siloed systems, you can’t have efficient, integrated workflows. People have to jump from one system to another, often needing to import-export data along the way. Having a system that uses open standards and is designed for collaboration, lets you tune and integrate processes to save time and money.

And that proprietary hardware costs a lot not only to buy, but set up and maintain too. You already have a network in your warehouse. Why not have a system that leverages the hardware you already have and use? Most legacy Bluetooth and RFID gateways are costly and force your IT department to maintain yet-another-system on top of all the other mission critical ones you have running.

And then there’s the people side. People make mistakes. If someone is standing and scanning all day, things might get missed or double scanned, or the wrong thing could be scanned. Even things as simple as importing data from a data logger can go wrong. It’s much better to have systems that automatically receive your cold chain monitoring data and import it into your existing systems. Then you can give people easy-to-understand dashboards that alert them when there is a problem, even before the shipment arrives. When you can automate data gathering and reporting, you can use your scarce human assets more efficiently. Put people on the tasks that people do best, and let computers do the rest.

Luna XIO looked at how things have been done in the past and found a better way. They developed an award-winning communications protocol to gather and transmit data from any BLE device through the cloud to your own systems securely and seamlessly–and do it using the hardware, infrastructure, and devices you already have.

Better connections (not just during Valentines day) is what makes the difference

Effective cold chain management needs constant connectivity. You can’t protect millions of dollars worth of perishables (flowers, food, or medicines) if you don’t have the data to make decisions. Data stuck in a data logger until the shipment arrives doesn’t do you any good.

Luna took a different approach.

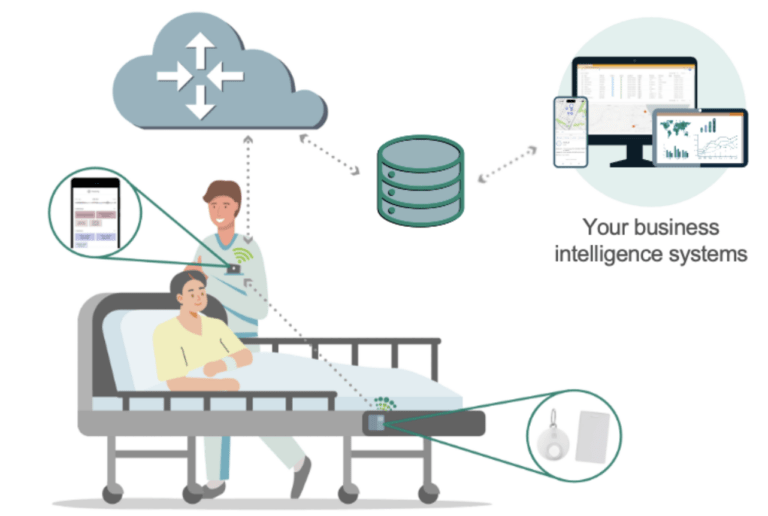

What if you leveraged the internet-connected devices all around you as gateways? What if software on company smartphones, mobile computers, and barcode scanners could receive data from the BLE sensors and then securely transmit it to the cloud?

Luna imagined a system where you could use any device to connect to any sensor and securely send data to your systems. Something that didn’t mean you needed to buy fancy or expensive hardware. Something that used open standards and protocols for connectivity and standardized development APIs to get the data where it needed to be when it needed to be there.

Luna’s app can be deployed on company devices through your device management system, and then automatically gather and relay data to the cloud. Even if there are gaps in connectivity, as soon as Luna can connect to the internet, it transmits timestamped data in a batch to the cloud. In the meantime, Luna can still alert drivers if something is wrong via their mobile phones.

Because Luna uses virtually any device as a gateway, you don’t need to invest in specialized or expensive communications infrastructure; you’re using what you already have in place. Other solutions can’t deliver this kind of connectivity. Only Luna’s Bluetooth-to-cloud solution delivers secure and reliable data transmission in real time, so you can make decisions in real time.

Blossoming technology: Luna XIO meeting the challenge for cold chain monitoring and more

Luna XIO took the approach that:

- Getting data in real time is a must have for today’s supply chains

- Using standards-based and non-proprietary protocols makes the system more reliable and extensible

- You should be able to use your existing devices and infrastructure

- You should be able to pick the right sensor for the job, not the sensor someone wants to sell you

- Data should be protected and encrypted at all times with ‘zero trust’ security

- Systems should work together to improve your existing workflows, not create new ones

- You should be able to set everything up in a week without needing to touch every device or sensor you have

While having real-time data is essential for cold chain monitoring, Luna and BLE sensors can be used for everything from asset management to tracking regular shipments. Today’s BLE sensors are so small and inexpensive that it’s possible to have tracking data right to the pallet level. Drivers can be alerted when even a couple pallets are exceeding environmental parameters.

And everything is managed automatically. The Luna app picks up BLE signals, receives the data and sends it to the cloud without people needing to scan barcodes or RFID tags. Just being close to the sensor is enough. Luna’s technology leverages devices and your entire network as a massive system of relays so there are no dead zones in warehouses or gaps in buildings.

Luna’s approach has been so groundbreaking it has been recognized for this innovative technology by The International Society of Service Innovation Professionals with the Overall Impact – Business, Society, Innovation Award.

In the past, this kind of system would require manually configuring each sensor and each device to work together creating months of work just to set up and even more to make the system operational. Luna’s zero touch set up means you can deploy everything in a week and have data integrated into your existing systems. The Luna app for iOS and Android is self-configuring so employees don’t have to worry about getting the app working, it will just work. Sensors can be preconfigured, deployed, and added as you need them.

Without additional, expensive infrastructure to buy, and a pay-as-you-go model. Luna XIO is a smart and cost-effective solution that will level up your entire shipping and asset tracking system.

Learn more about how Luna improves supply chain visibility whether something has to stay cold or just get where it needs to go and book a consultation with us.

Don’t let your supply chain wilt like last year’s roses. Keep your blooms and business blossoming with Luna Supply Chain Visibility 2.0 and nip those logistical nightmares in the bud!