Real-time Asset Tracking. Made Easy.

Spending hours searching for assets? Real-time asset tracking is now easier and more affordable than ever.

In hospitals, warehouses, and manufacturing plants, misplaced equipment and inventory slow everything down. Real-time asset tracking used to be complex and expensive—it no longer has to be

Now, you can deploy a simple solution in less than a day.

If you’ve ever asked:

- “How did an entire shipment just disappear?”

- “Where are the extra oxygen tanks? We’re supposed to have three more.”

- “If we don’t get those parts in two hours, the entire line shuts down. Didn’t they come in today?”

Then you already know the problem.

It’s not always human error—sometimes an item is just placed where there’s space at the moment and forgotten. A crash cart gets moved to clear a hallway. A pallet is tucked behind others and vanishes from sight.

And just like that, it’s lost.

Then begins the search that wastes hours. Employees start with the obvious places, then move on to the “why would anyone put that here?” spots. Sometimes the item stays lost, requiring a costly replacement.

There’s a better way—real-time asset tracking ensures that nothing stays missing for long.

The real cost of lost equipment and inventory

Losing track of assets costs more than just the price of the item itself. The financial impact, wasted time, and operational inefficiencies add up fast.

Scenario 1: A ‘Just-in-Time’ Shipment Goes Missing

Nearly every factory relies on just-in-time parts deliveries. Keeping only what’s needed for the next shift reduces storage costs, but it also means there’s no margin for error—every part needs to be accounted for.

Imagine this: A shipment arrives at Receiving. Just as it’s about to be staged, an accident happens—a forklift knocks over barrels of hydraulic fluid. Fire rescue arrives, paramedics attend to an injured worker, and the focus shifts to cleanup.

In the chaos, the shipment is moved aside to clear space. But no one logs where it was placed. The system still shows the parts are in Receiving.

Hours later, the assembly line foreman requests the parts. The system says they should be in staging, but they’re nowhere to be found. Calls go back and forth between Receiving and Staging—“We dropped them off hours ago!”

A frantic two-hour search across acres of warehouse space finally turns up the missing pallets, tucked into a forgotten corner. But it’s too late—the production line had to shut down, and now workers must log costly overtime to recover lost time.

Total cost? Tens of thousands of dollars in wasted productivity and unnecessary delays.

Scenario 2: A Missing Defibrillator in a Hospital Emergency

In hospitals, every second counts. Equipment is often borrowed between floors, and while that’s standard practice, it’s easy for items to end up in the wrong place.

A defibrillator from one floor is temporarily loaned to another. When it’s returned, someone leaves it in a hallway, planning to put it away later. But later never comes. The defibrillator is shuffled around—out of the way, into a supply closet.

Hours later, a patient goes into cardiac arrest. One defibrillator is already in use, and the second one is missing. Nurses scramble—checking other floors, searching storage areas, trying to find it.

Eventually, it’s located—hidden just inside a closet. The patient survives. No harm done… this time.

Stop wasting time searching. Get real-time asset tracking

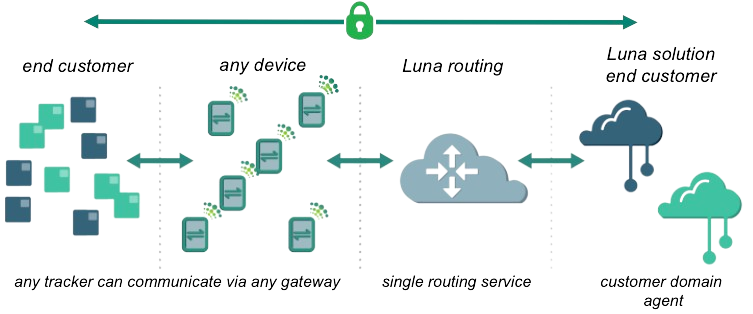

The solution isn’t complicated. Real-time asset tracking with Bluetooth Low Energy (BLE) tags provides instant location data—without expensive infrastructure or complex installations.

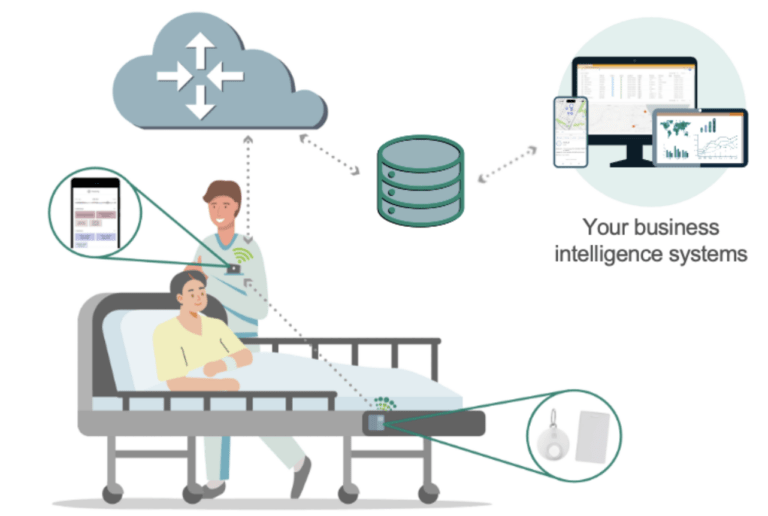

However, BLE tags alone aren’t enough. You need a system that can track them in real-time, even in network dead zones. That’s where Luna XIO changes the game.

How Luna XIO Works

Luna XIO turns existing work smartphones, tablets, WiFi-enabled printers, and other connected devices into asset-tracking gateways. Instead of expensive infrastructure, it uses what’s already in your facility.

✅ Fast deployment: Set up in a day, with no new hardware required

✅ Real-time tracking: See exactly where assets are—and where they shouldn’t be

✅ Encrypted, secure data: All asset and location data is protected end-to-end

✅ No extra training: The Luna app works seamlessly on iOS and Android, requiring minimal user input

If an asset is misplaced, Luna instantly shows where it actually is, based off the data the tag sends through all the Luna-enabled gateways.

How Luna Prevents Costly Mistakes

🔹 Scenario 1: The Missing Parts—Located Instantly

With real-time asset tracking, the misplaced parts wouldn’t have required a warehouse-wide search.

Luna would have automatically logged their location when they were moved. When the foreman needed them, he wouldn’t have to guess—Luna’s dashboard would have shown exactly where they were, eliminating delays and costly downtime.

🔹 Scenario 2: The Missing Defibrillator—Always Accounted For

With Luna, the defibrillator’s movements would have been tracked automatically. If it was placed in the wrong spot, the system would have flagged it. Before a crisis even happened, an alert could have reminded staff to return it to the correct location.

No searching. No delays. No risk.

Every minute spent searching for lost assets is a minute wasted. Luna XIO makes it effortless to track, locate, and recover assets instantly—without the cost and complexity of traditional tracking solutions.

Here is a short video showing how Luna asset tracking works in the automotive industry:

One Comment

Comments are closed.